| CCR - SCR Calculations

by B.R. Wienke and T.R. O’Leary (NAUI Tech Ops)

A rebreather (RB) is any self-contained breathing apparatus that recycles a diver’s breathing mixture. Recycling requires a closed loop for the breathing source and exhaust gas. Additionally, to reuse breathing gases, a scrubbing agent is needed to remove carbon dioxide from the loop. A bag or counterlung is needed to capture the diver’s exhaled breathing gasses. The combination of gas mixtures, hoses and mouthpieces, counter lung, and scrubber is called a breathing loop. Operationally, RBs vary widely in design and efficiency, but they are generally broken into two categories, closed circuit rebreathers (CCRs) and semi-closed circuit rebreathers (SCRs). Furthermore, CCRs can employ both pure oxygen or another mixed gas (diluent) plus oxygen. SCRs usually employ just a mixed gas diluent.

What are the concerns of RB divers?

Divers using RBs must concern themselves with both oxygen toxicity and possible decompression constraints. On pure oxygen, oxygen toxicity is the only concern, but with mixed gas diluents, decompression may be required. Of course, the higher the oxygen partial pressure, ppO2, the shorter the decompression requirements on mixed gas diluents, but the higher the oxygen partial pressure, the greater the risk of oxygen toxicity. Most RB divers maintain a ppO2 near the 1.4 atm level, which has an oxygen time limit in the 140 min range.

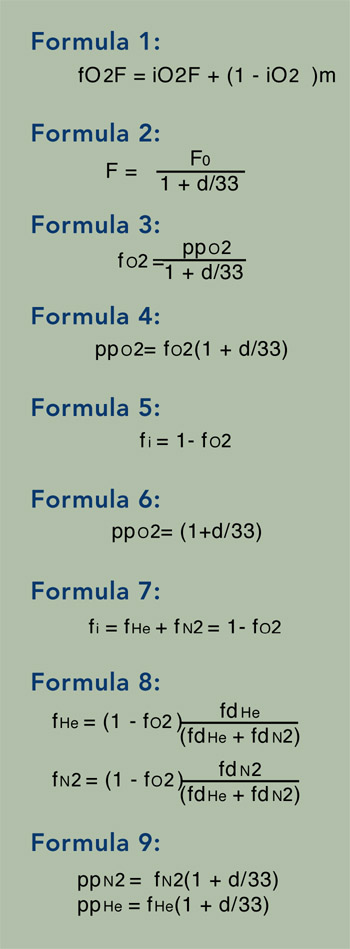

Crucial to the operation of RBs is a constant and continuous mass flow of breathing gas, subject to oxygen metabolic requirements and depth. Mass balance simply requires that the flow into the breathing bag equals the amount used by the body plus that exhaled into the breathing bag or exhalation bag. Denoting the breathing gas flow rate, F, the metabolic oxygen (consumption) rate, m, the source oxygen fraction, fO2, and inspired (breathing bag) oxygen fraction, iO2, mass balance is determined, (see formula 1). The source flow rate, F, and oxygen fraction, fO2, depend on nozzle and mixture. The metabolic rate, m, depends on workload, and the inspired fraction, iO2, is uniquely determined with the other three specified. Or, for requisite inspired fraction, iO2, and metabolic rate, m, the source rate, F, and oxygen source fraction, fO2, can be fixed within limits. Workload rates, m, range 0.5 to 20.5 l/min, while source flows, F, depend on depth, cylinder and nozzle, with typical values, 5 to 16 l/min. As seen, the source oxygen fraction, fO2, is uniquely determined by the maximum depth, dmax, and maximum oxygen pressure (typically 1.6 to 1.4 atm). Always, inspired oxygen partial pressures are kept between hyperoxic and hypoxic limits, roughly, 0.16 to 1.6 atm. At depth, d, the source flow rate, F, decreases according F0, the surface rate, (see formula 2) unless the flow is depth compensated.

Want constant oxygen partial pressure or constant oxygen fraction?

All RBs strive for either constant oxygen partial pressure, ppO2, or oxygen mix fraction, fO2, or something in between for dive depth limits, through a combination of injectors, sensors, and valves. High operational oxygen partial pressures coupled to lower inert gas partial pressures minimize decompression requirements, obviously, but oxygen toxicity concerns are raised. For fixed oxygen partial pressure, ppO2 in atm, the oxygen fraction, fO2, depends on depth, d, (see formula 3). For fixed oxygen fraction, fO2, oxygen partial pressure varies, (see formula 4). In both cases, the total inert gas fraction, fi, is always given, (see Formula 5) and varies little when fO2 is relatively constant.

How do CCRs and SCRs differ?

They all deliver constant ppO2 or (roughly) constant fO2, but there are some major difference’s impacting the RB diver.

Closed circuit RBs

Pure oxygen CCRs are relatively simple devices, employing just oxygen in the breathing mixture. Obviously, there are no inert gas decompression requirements on pure oxygen. Oxygen toxicity (CNS and full body), however, is a major concern on oxygen CCRs. In such a device, the volume of gas in the breathing loop is constantly maintained, and oxygen is added to compensate for metabolic consumption and increasing pressure. On ascent, the breathing gas must be vented if it is not consumed metabolically. Oxygen CCRs inject pure oxygen into the breathing loop, so that fO2 = 1, with corresponding oxygen partial pressure (atm), (see formula 6) for sea level activities. Because of oxygen toxicity concerns, oxygen CCRs are limited for diving, somewhere in the 20 to 30 fsw range to keep the ppO2 below 1.6 atm.

Mixed gas CCRs allow deeper excursions than pure oxygen CCRs by diluting the breathing mix with inert gases, notably nitrogen and helium. Fresh oxygen is injected into the breathing loop only as needed to compensate for metabolic oxygen consumption. Partial pressures of oxygen are measured in the loop with oxygen sensors, and oxygen is injected to maintain constant oxygen partial pressures called the set point. Operationally, mixed gas CCRs are simpler to use than their sisters, mixed gas SCRs. Efficiency and safety concerns obviously track directly to oxygen sensors. Mixed gas CCRs maintain constant oxygen partial pressures, ppO2, with a combination of diluents and pure oxygen. The oxygen fraction, fO2, varies with depth, (see formula 3) and the breathed total inert gas fraction, fi, makes up the deference, (see formula 7) for the general case of helium and nitrogen diluents. The oxygen, helium, and nitrogen breathed gas fractions, fO2, fHe, and fN2 vary continuously with depth, d. If the (fixed) diluent helium and nitrogen fraction are denoted, fdHe and fdN2, the breathed helium and nitrogen fractions become (see formula 8). Partial pressures at depth for the inert gases are then simply, (see formula 9) and the oxygen partial pressure, ppO2, is constant.

Semi-closed circuit RBs

A semi-closed circuit rebreather (SCR) is very similar to a CCR but operates with an overpressure relief valve to vent gas in maintaining ambient pressure in the loop. A metering valve is necessary to assess metabolic oxygen consumption and breathing gas injection rates. A number of injection systems exist and all are designed to compensate for metabolic oxygen consumption:

1. Constant Ratio Injection

SCRs in this category have an oxygen and diluent gas source. Diluent injection varies with depth and oxygen injection links to a mass transport control system. The injection strategy approaches constant ppO2 performance in the breathing loop. In this case, the fraction, fO2, varies with depth, (see formula 3) and breathed total inert gas fraction, fi, makes up the difference, (see formula 7) as before for mixed gas CCRs. Retaining diluent fractions, fdHe and fdN2, breathed helium and nitrogen fractions remain, (see formula 8). Partial pressures at depth for the inert gases are still (see formula 9).

2. Constant Mass Flow Injection

A set gas mixture point controls a constant flow of diluent into the loop. Exhaust is vented through an overpressure relief valve. A single diluent source is employed, while in constant mass flow SCRs, both oxygen partial pressure and oxygen fraction are more variable than in all other RB devices. For depth ranges anticipated, minimal and maximal values of oxygen fraction, fO2, can be determined from the mass balance equation and used for dive planning contingencies, such as oxygen toxicity and decompression, from the above set of equations (see formula 4).

3. Respiratory Volume Injection

This SCR is a variant of the constant mass flow device. The injection rate of diluent is coupled to the diver’s breathing rate, maintaining an almost constant fraction, fO2, in loop oxygen. A single diluent source is again used. Operationally, a fairly constant fO2 results, and oxygen partial pressure, ppO2, varies with depth, (see formula 4) and breathed total inert gas fraction, fi, makes up the difference, (see formula 7) as above. With the same diluent fractions, fdHe and fdN2, breathed helium and nitrogen fractions are roughly constant also, (see formula 8).

Breathed inert gas partial pressures vary at depth, (see formula 9) and the oxygen partial pressure, ppO2, varies as indicated above. To achieve such ends in flow programming, RBs are very complex systems. Extensive diver training and technical knowledge are keynoted in RB diving and usage. Are RBs the most efficient means to deep and extended diving short of surface supplied gas and decompression pods? I guess we would vote yes.

|

|

|